Understanding Custom Pipe Fabrication

Custom pipe fabrication involves the creation of specialized piping systems designed to exact specifications. Unlike off-the-shelf solutions, custom fabrication offers unparalleled flexibility, allowing companies to address unique challenges and optimize operational efficiency. Whether it's complex geometries, specific materials, or precise dimensions, custom pipe fabrication caters to diverse requirements with precision and expertise.

Applications Across Industries

● The versatility of custom pipe fabrication finds applications across a myriad of industries. In the oil and gas sector, custom pipes are essential for transporting crude oil, natural gas, and refined products over vast distances, often through challenging terrains and harsh environments. The petrochemical industry relies on custom pipes for processing facilities, ensuring the safe and efficient transfer of chemicals and gases.

● Manufacturing facilities leverage custom pipe fabrication for their intricate HVAC systems, providing precise temperature control and ventilation to optimize production processes. In the pharmaceutical and biotechnology sectors, custom pipes play a critical role in sterile processing, maintaining the integrity of sensitive materials, and meeting stringent regulatory standards.

● From water treatment plants to aerospace engineering, custom pipe fabrication is integral to infrastructure development, environmental conservation, and technological innovation across the board.

Advantages of Custom Pipe Fabrication

Tailored Solutions: Custom pipe fabrication allows for the creation of piping systems tailored to specific needs, ensuring optimal performance and efficiency.

Precision Engineering: Expert fabricators employ advanced techniques and technologies to produce pipes with exact dimensions and specifications, minimizing waste and maximizing functionality.

Quality Assurance: Rigorous quality control measures ensure that custom pipes meet industry standards and regulatory requirements, guaranteeing reliability and safety in operation.

Cost Efficiency: While custom fabrication may involve higher upfront costs than off-the-shelf solutions, it offers long-term savings by minimizing downtime, reducing maintenance needs, and maximizing operational efficiency.

Flexibility and Adaptability: Custom pipes can be designed to accommodate future expansions or modifications, providing scalability and adaptability to changing operational requirements.

Key Considerations in Custom Pipe Fabrication

Material Selection: The choice of material depends on factors such as operating conditions, fluid compatibility, and budget constraints. Common materials used in custom pipe fabrication include stainless steel, carbon steel, aluminum, and various alloys.

Design Engineering: Collaboration between engineers, designers, and fabricators is crucial in translating project requirements into functional designs. Advanced CAD software enables precise modeling and simulation to optimize performance and minimize errors.

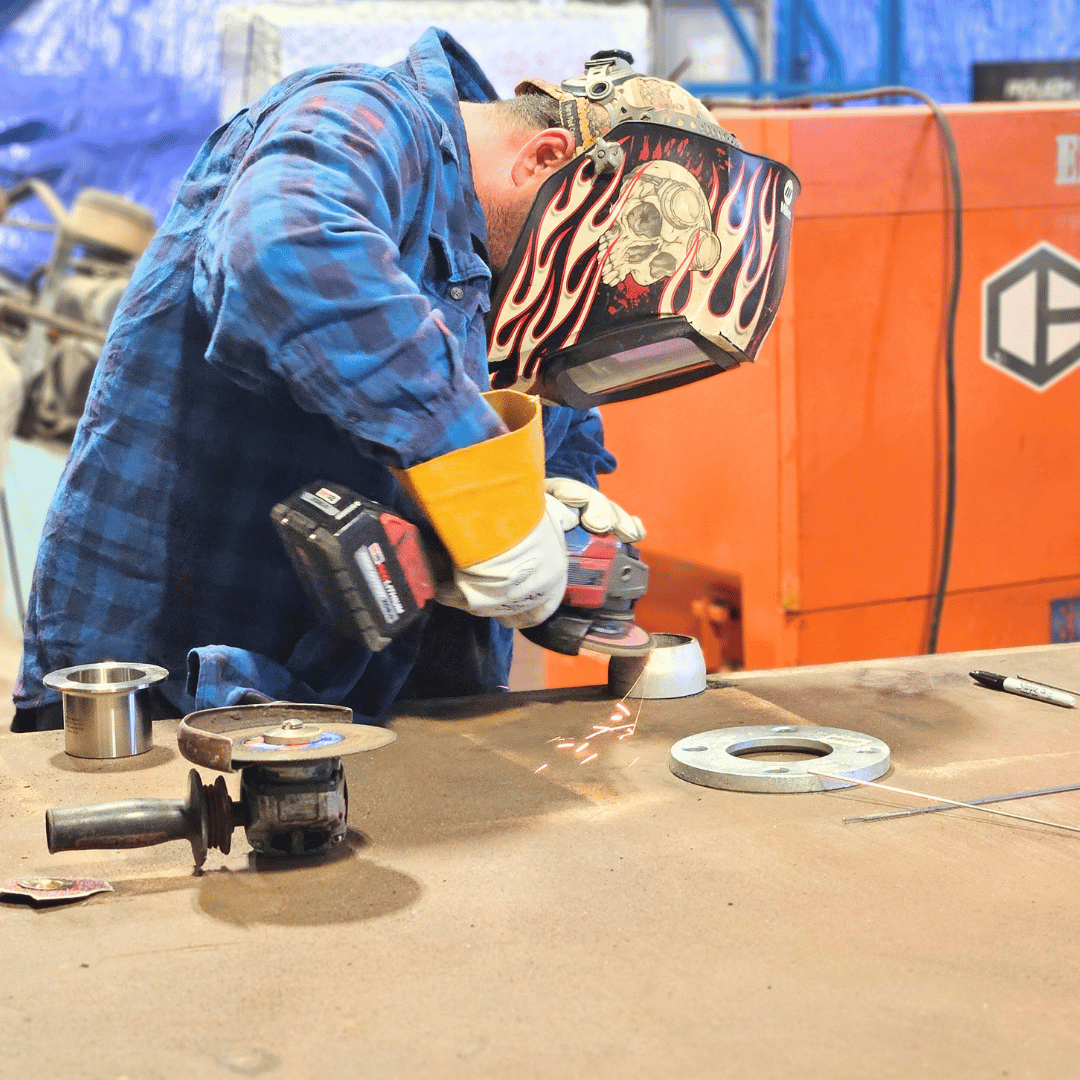

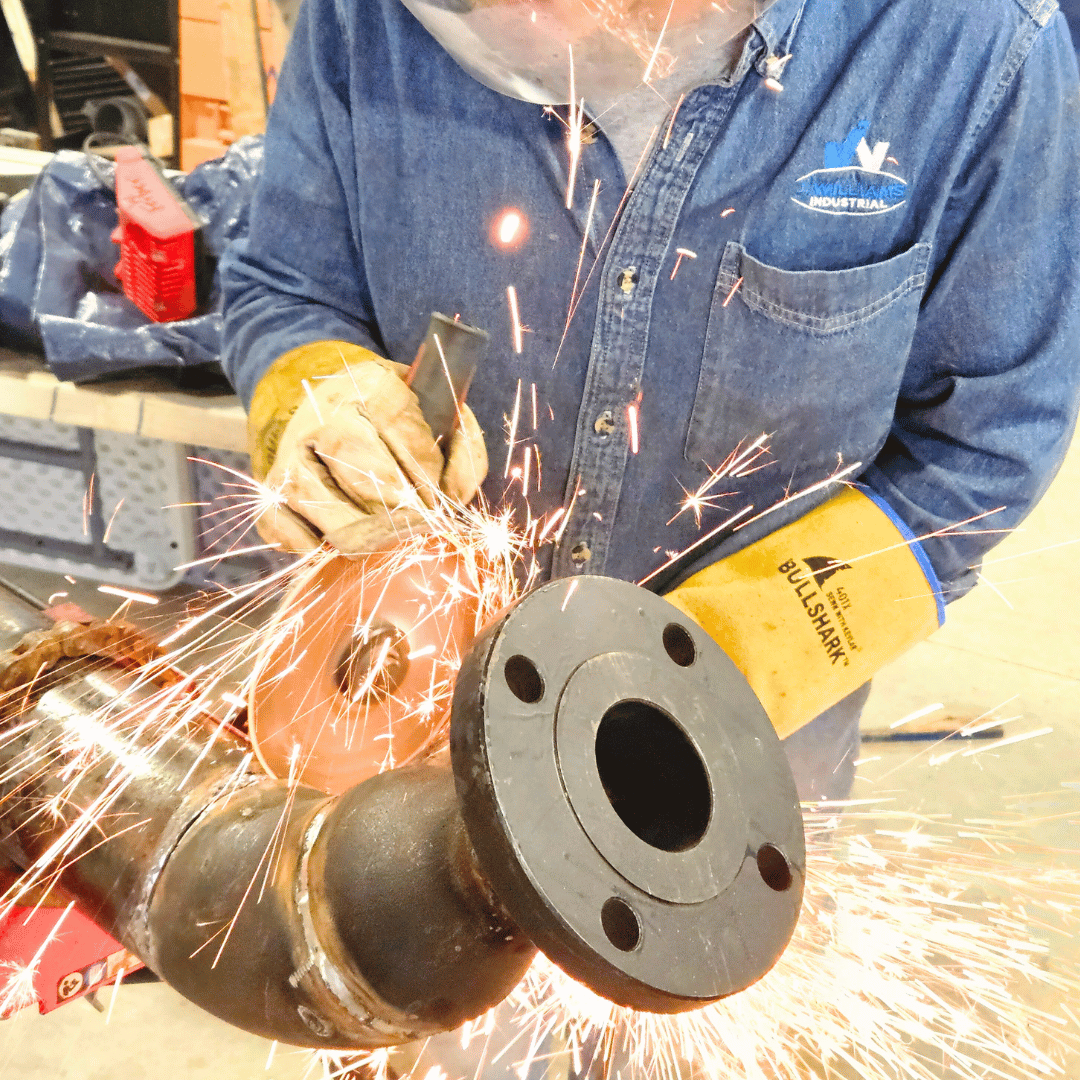

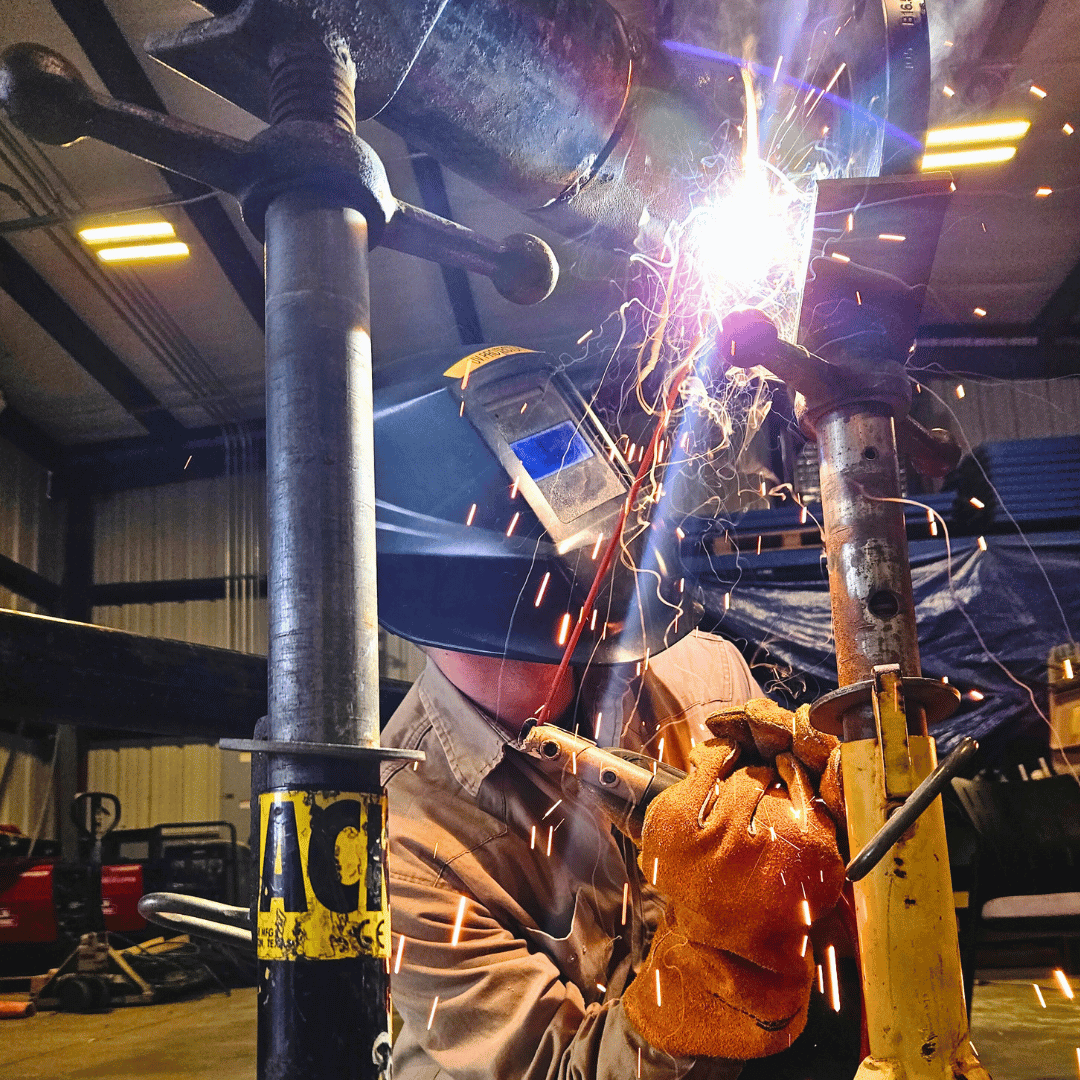

Fabrication Techniques: Welding, bending, machining, and coating are among the primary fabrication techniques employed in custom pipe manufacturing. Skilled craftsmen utilize a combination of manual expertise and automated machinery to ensure accuracy and consistency.

Quality Control: Stringent quality assurance protocols encompass material inspection, dimensional accuracy checks, weld integrity testing, and surface finish evaluation. Compliance with industry standards such as ASME, ASTM, and API is paramount in ensuring the reliability and safety of custom pipes.

Installation and Maintenance: Proper installation procedures and preventive maintenance schedules are essential for maximizing the lifespan and performance of custom piping systems. Regular inspections, corrosion protection measures, and leak detection protocols help identify potential issues early and mitigate risks.

The Future of Custom Pipe Fabrication

As industries evolve and technologies advance, the demand for custom pipe fabrication is poised to grow further. Emerging trends such as 3D printing, automation, and digital twin simulations are revolutionizing the fabrication process, offering new possibilities in design complexity, material optimization, and production efficiency.

The increasing focus on sustainability and environmental stewardship is driving innovations in materials and manufacturing techniques, leading to the development of eco-friendly piping solutions with reduced carbon footprints and enhanced recyclability.

Conclusion

Custom pipe fabrication is not just about building pipes; it's about crafting solutions that empower industries to overcome challenges, achieve operational excellence, and drive progress. By harnessing the expertise of skilled fabricators, embracing technological advancements, and prioritizing quality and safety, businesses can unlock the full potential of custom pipe fabrication in an ever-evolving world.