The Importance of Hydrostatic Testing

Over time, fire extinguisher cylinders are exposed to pressure changes, environmental conditions, and general wear and tear. Hydrostatic testing helps to verify that these cylinders are still structurally sound and can safely hold pressure in an emergency.

Benefits of Hydrostatic Testing

- ● Ensure Equipment Safety: Hydrostatic testing verifies that your fire extinguishers are safe to use and won’t fail when needed.

- ● Maintain Compliance: Regular testing keeps your equipment compliant with NFPA 10 and OSHA regulations.

- ● Extend Equipment Lifespan: Identifying potential issues early through testing can extend the life of your fire extinguishers, reducing long-term replacement costs.

Our Fire Extinguisher Hydrostatic Testing Process

Our certified technicians follow a detailed procedure to ensure your fire extinguisher cylinders can hold pressure safely and effectively. We adhere to all safety standards, using specialized equipment to test the integrity of your fire extinguishers.

- Cylinder Inspection: We start by visually inspecting the cylinder for cracks, corrosion, or other signs of wear and tear.

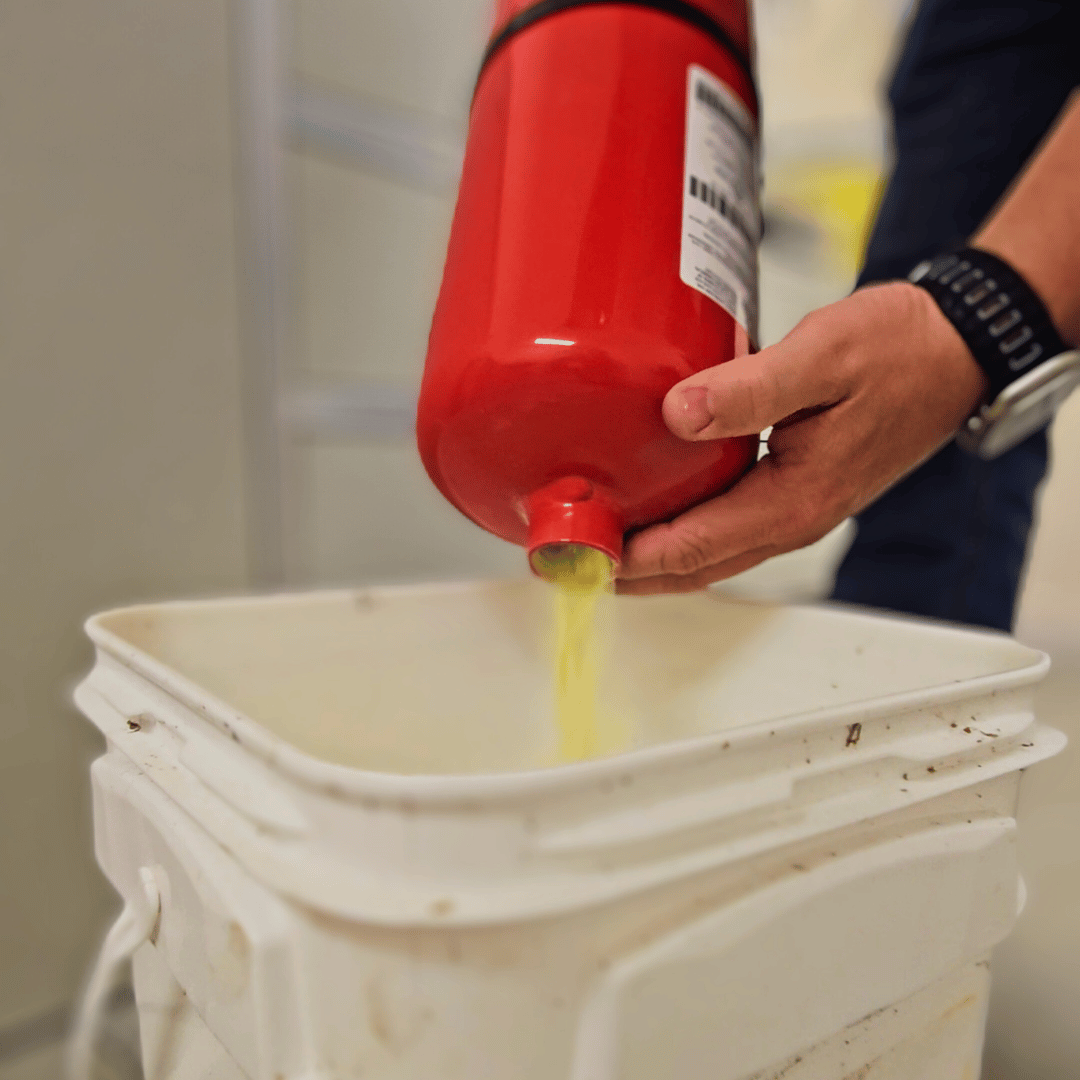

- Discharge & Pressure Release: The extinguisher is safely discharged, and all pressure is released before testing begins.

- Hydrostatic Testing: The cylinder is filled with water and pressurized beyond its normal operating limits to ensure it can hold pressure without leaking or deforming.

- Drying & Reassembly: Once testing is complete, the extinguisher is dried, reassembled, and refilled with the appropriate extinguishing agent.

- Testing Results & Documentation: A detailed report is provided, and service tags are updated to reflect compliance with hydrostatic testing schedules.

Our testing process ensures that your fire extinguishers are fully functional and meet all regulatory requirements.

Compliance & Safety

Hydrostatic testing is an essential part of fire extinguisher maintenance, required by NFPA 10 and OSHA to ensure the cylinder’s integrity and ability to withstand pressure. Failing to conduct hydrostatic tests on schedule can result in non-compliance, fines, or, worse, malfunction during an emergency.

Key Benefits

- ● Ensure compliance: Meet NFPA 10 and OSHA fire safety regulations.

- ● Verify structural integrity: Confirm the cylinder’s ability to withstand pressure.

- ● Prevent malfunctions: Avoid failures caused by compromised extinguishers.

Why Choose Us for Hydrostatic Testing?

We provide certified hydrostatic testing services tailored to the unique needs of industrial and commercial businesses. With years of experience in fire safety, we ensure that your equipment is tested accurately and on schedule to keep you compliant with NFPA and OSHA standards.

What Sets Us Apart

- ● Certified Technicians: Our team is fully certified to conduct hydrostatic testing on all types of fire extinguishers, following the latest safety standards.

- ● Advanced Testing Equipment: We use state-of-the-art equipment to ensure accurate and reliable testing results.

- ● Comprehensive Services: In addition to testing, we provide recharging, maintenance, and documentation to keep your fire extinguishers in top condition.

FAQ Section

Q: How often do fire extinguishers need hydrostatic testing?

A: Most fire extinguishers require hydrostatic testing every 12 years, but certain types may need testing more frequently. We can assess your fire extinguishers and ensure that testing schedules are properly followed.

Q: What happens if a fire extinguisher fails the hydrostatic test?

A: If a fire extinguisher cylinder fails the hydrostatic test, it must be replaced immediately. We will provide recommendations for repair or replacement based on the condition of your equipment.

Q: Why is hydrostatic testing important for fire extinguishers?

A: Hydrostatic testing ensures that the fire extinguisher cylinder can hold the pressure required to function properly in an emergency. Without this test, there is a risk of equipment failure due to leaks or weakened structure.