Understanding Industrial Plumbing Systems Installation

Industrial plumbing systems installation involves the meticulous planning, design, and implementation of plumbing networks tailored to meet the unique demands of industrial facilities. These systems encompass many components, including pipes, valves, pumps, fixtures, and drainage systems, intricately integrated to facilitate the flow of water, gases, chemicals, and other fluids essential for industrial processes.

Significance of Industrial Plumbing Systems

The significance of industrial plumbing systems extends far beyond the mere conveyance of fluids. These systems serve as the lifelines of industrial operations, ensuring the uninterrupted supply of water for various purposes such as cooling, cleaning, and processing. Moreover, they play a crucial role in maintaining environmental sustainability by managing wastewater disposal and adhering to regulatory standards.

Key Components of Industrial Plumbing Systems

Pipes: Industrial plumbing systems utilize a diverse range of pipes, including steel, copper, PVC, and various alloys, selected based on fluid type, pressure, temperature, and corrosiveness.

Valves: Valves act as control mechanisms to regulate the flow of fluids within the plumbing network, enabling operators to adjust pressure, direction, and volume as required.

Pumps: Industrial pumps play a pivotal role in boosting water pressure, facilitating the transfer of fluids over long distances, and maintaining optimal flow rates within the system.

Fixtures: Fixtures such as faucets, sinks, and toilets are integrated into industrial plumbing systems to provide access points for water usage and disposal, ensuring functionality and convenience for workers.

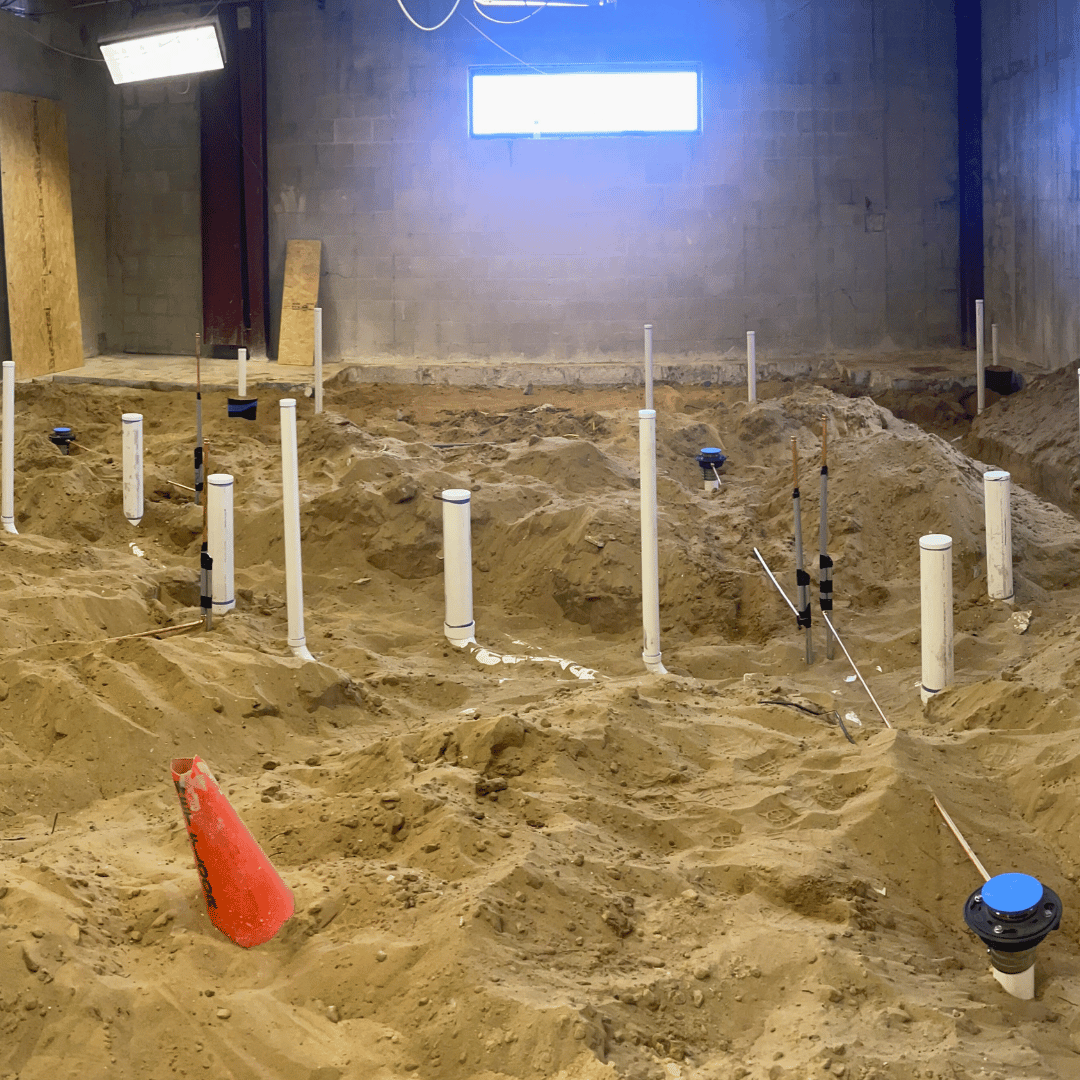

Drainage Systems: Effective drainage systems are essential for managing wastewater and preventing flooding or contamination incidents. These systems incorporate drains, traps, and vents to facilitate the safe removal of liquids and gases from industrial facilities.

Installation Procedures

Industrial plumbing systems installation follows a systematic approach encompassing several key phases:

● Assessment and Planning: The installation process begins with a comprehensive assessment of the facility's requirements, taking into account factors such as water demand, system layout, regulatory compliance, and budget constraints. Detailed planning ensures that the plumbing system is designed to meet the specific needs of the industrial operation.

● Material Selection: Choosing the right materials is crucial for the longevity and efficiency of the plumbing system. Factors such as material compatibility, durability, and cost-effectiveness are carefully considered during the selection process.

● Preliminary Work: This phase involves preparatory tasks such as site preparation, excavation, and rough-in plumbing, laying the groundwork for the installation of pipes, fixtures, and other components.

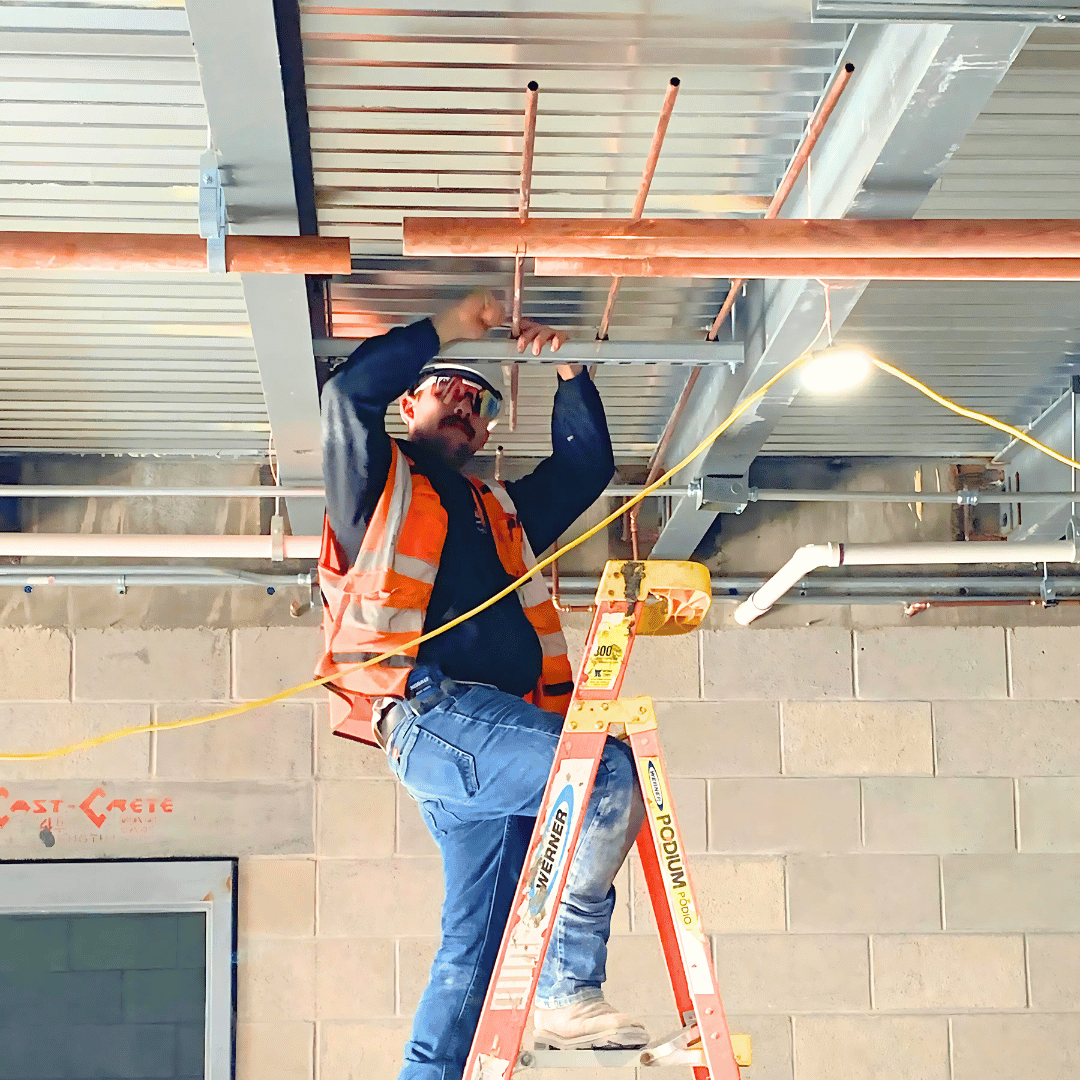

● Installation and Assembly: Skilled technicians and plumbers execute the installation process, meticulously assembling the plumbing system according to the approved design plans. This phase includes pipefitting, welding, soldering, and the integration of valves, pumps, and fixtures.

● Testing and Inspection: Upon completion of the installation, rigorous testing and inspection procedures are conducted to ensure the integrity and functionality of the plumbing system. Pressure tests, leak detection, and flow rate assessments are performed to verify compliance with industry standards and regulatory requirements.

● Commissioning and Maintenance: Once the plumbing system passes inspection, it is commissioned for operation. Regular maintenance and servicing are essential to preserve the system's efficiency, detect potential issues early, and prolong its service life.

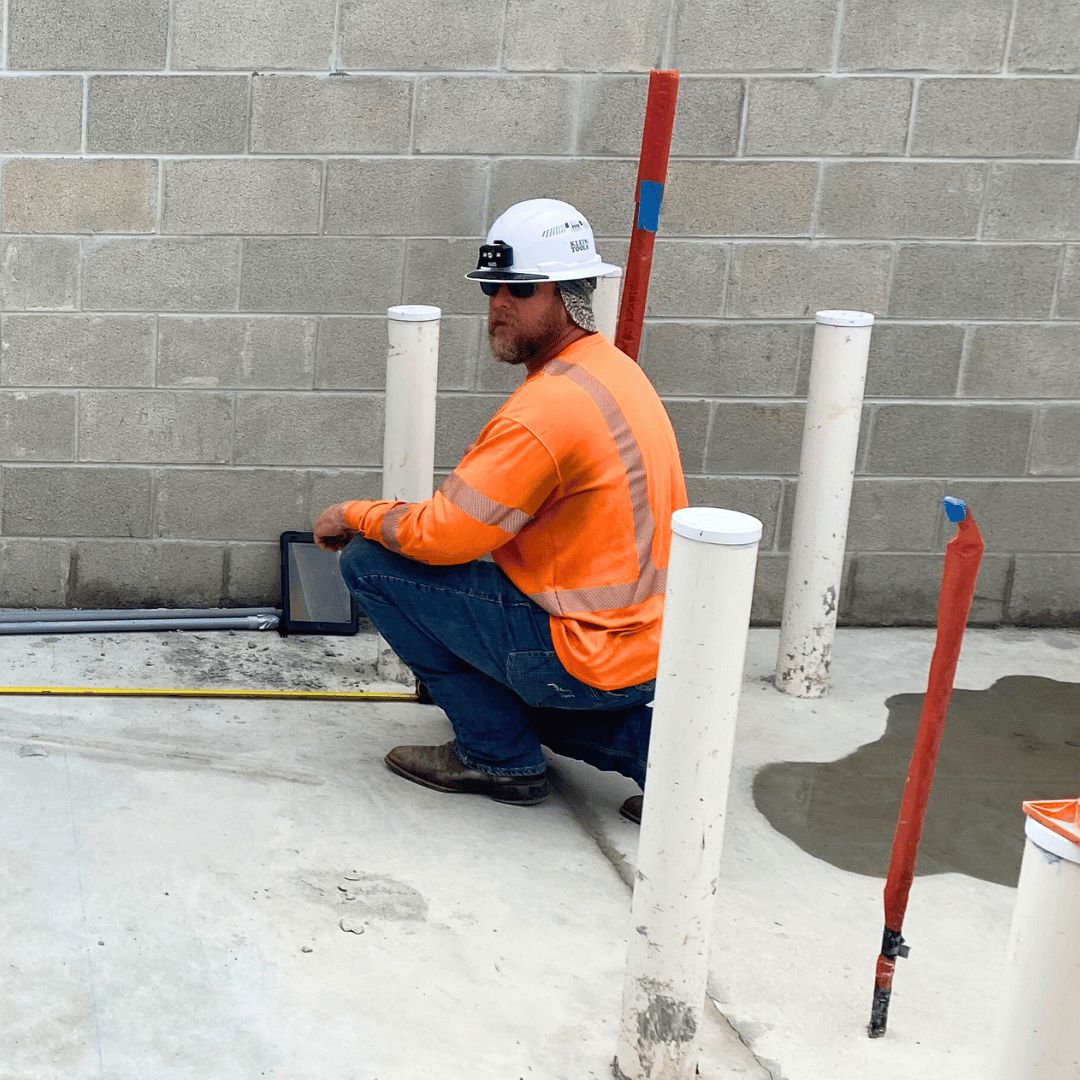

The Role of Professionals in Industrial Plumbing Installation

Industrial plumbing systems installation demands a high level of expertise, precision, and adherence to safety protocols. Employing certified plumbing professionals with specialized knowledge and experience in industrial settings is paramount to ensuring the successful implementation of complex plumbing projects. These professionals possess the skills and resources necessary to navigate the intricacies of industrial plumbing, mitigate risks, and deliver solutions that align with the client's objectives and regulatory requirements.

Conclusion

In conclusion, industrial plumbing systems installation forms the backbone of industrial infrastructure, supporting essential processes, promoting operational efficiency, and safeguarding environmental health and safety. By understanding the significance of industrial plumbing, the key components involved, and the meticulous installation procedures required, industrial facilities can ensure the seamless operation of their plumbing networks and lay the foundation for sustained productivity and success.