Understanding Industrial Motors

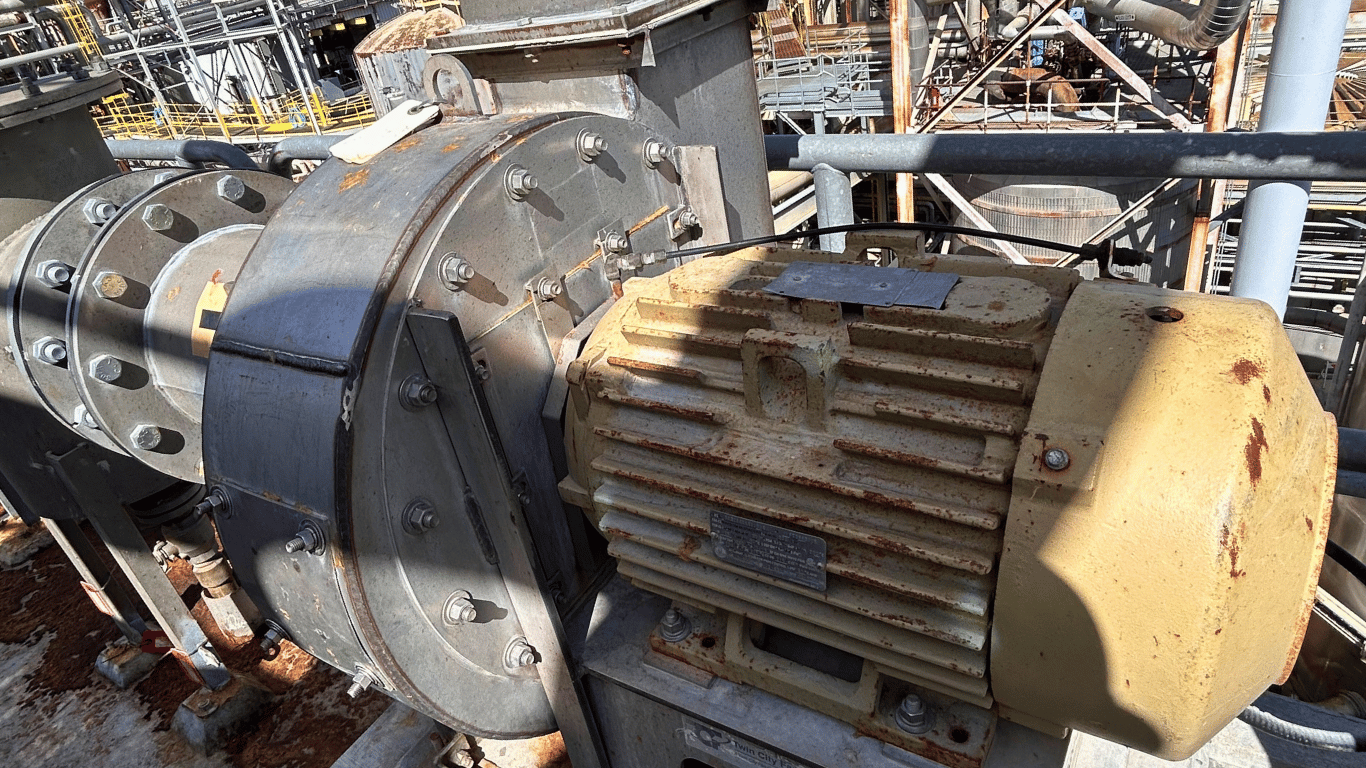

Before diving into installation and maintenance procedures, it's essential to understand the types and functions of industrial motors. These motors come in various types, including AC motors, DC motors, and specialized motors like servo motors and stepper motors. Each type has unique characteristics and applications, catering to specific industrial needs.

Installation Process

Pre-Installation Planning: Before installing an industrial motor, thorough planning is necessary. This includes assessing the motor's specifications, electrical requirements, and compatibility with existing machinery.

Site Preparation: Ensure the installation site is adequately prepared, with proper ventilation, space, and accessibility for the motor and associated equipment.

Mounting the Motor: Carefully mount the motor according to manufacturer guidelines, ensuring proper alignment and support to prevent vibration and misalignment issues.

Electrical Connection: Follow electrical wiring diagrams and safety protocols to connect the motor to the power source correctly. Ensure proper grounding and insulation to prevent electrical hazards.

Testing and Calibration: After installation, conduct thorough testing and calibration to ensure the motor operates smoothly and efficiently. Check for any abnormal noises, vibrations, or overheating issues.

Maintenance Practices

Regular Inspections: Implement a routine inspection schedule to check for signs of wear, damage, or malfunction in industrial motors. Inspect electrical connections, bearings, and cooling systems regularly.

Lubrication: Proper lubrication is essential for maintaining optimal motor performance and extending its lifespan. Follow manufacturer recommendations for lubrication intervals and types of lubricants.

Temperature Monitoring: Monitor motor temperatures during operation to prevent overheating, which can damage internal components. Install temperature sensors or thermal protection devices for automated monitoring and safety.

Cleaning and Dust Management: Keep motors clean and free from dust, debris, and other contaminants that can hinder performance and cause premature wear. Use compressed air or vacuum to remove dirt buildup regularly.

Alignment and Balancing: Periodically check motor alignment and balance to ensure smooth operation and prevent issues like bearing wear and shaft misalignment.

Conclusion

Proper installation and care of industrial motors are essential for ensuring optimal performance, reliability, and safety in industrial and commercial settings. By following best practices for installation, maintenance, and troubleshooting, businesses can maximize the efficiency and longevity of their motorized equipment, ultimately reducing downtime and maintenance costs.