What is Plumbing Infrastructure Inspection?

Plumbing infrastructure inspection involves a comprehensive assessment of all plumbing components within an industrial or commercial setting. This includes pipes, fixtures, valves, water heaters, drainage systems, and more. The primary objective of these inspections is to identify any existing or potential issues that could compromise the efficiency, safety, or compliance of the plumbing system.

Why is Plumbing Infrastructure Inspection Important?

- ● Preventive Maintenance: Regular inspections help identify minor issues before they escalate into major problems. By addressing issues early on, facility managers can prevent costly repairs and downtime.

-

- ● Compliance: Industrial and commercial facilities are subject to various regulations and codes related to plumbing systems. Regular inspections ensure compliance with these standards, avoiding penalties and legal issues.

-

- ● Safety: Malfunctioning plumbing systems can pose safety hazards such as leaks, floods, or contamination. Inspection helps detect and address these hazards to ensure a safe working environment for employees and customers.

-

- ● Optimized Efficiency: A well-maintained plumbing system operates more efficiently, reducing water waste and energy consumption. Inspection helps identify areas for improvement, such as upgrading to water-efficient fixtures or repairing leaks.

Key Components of Plumbing Infrastructure Inspection

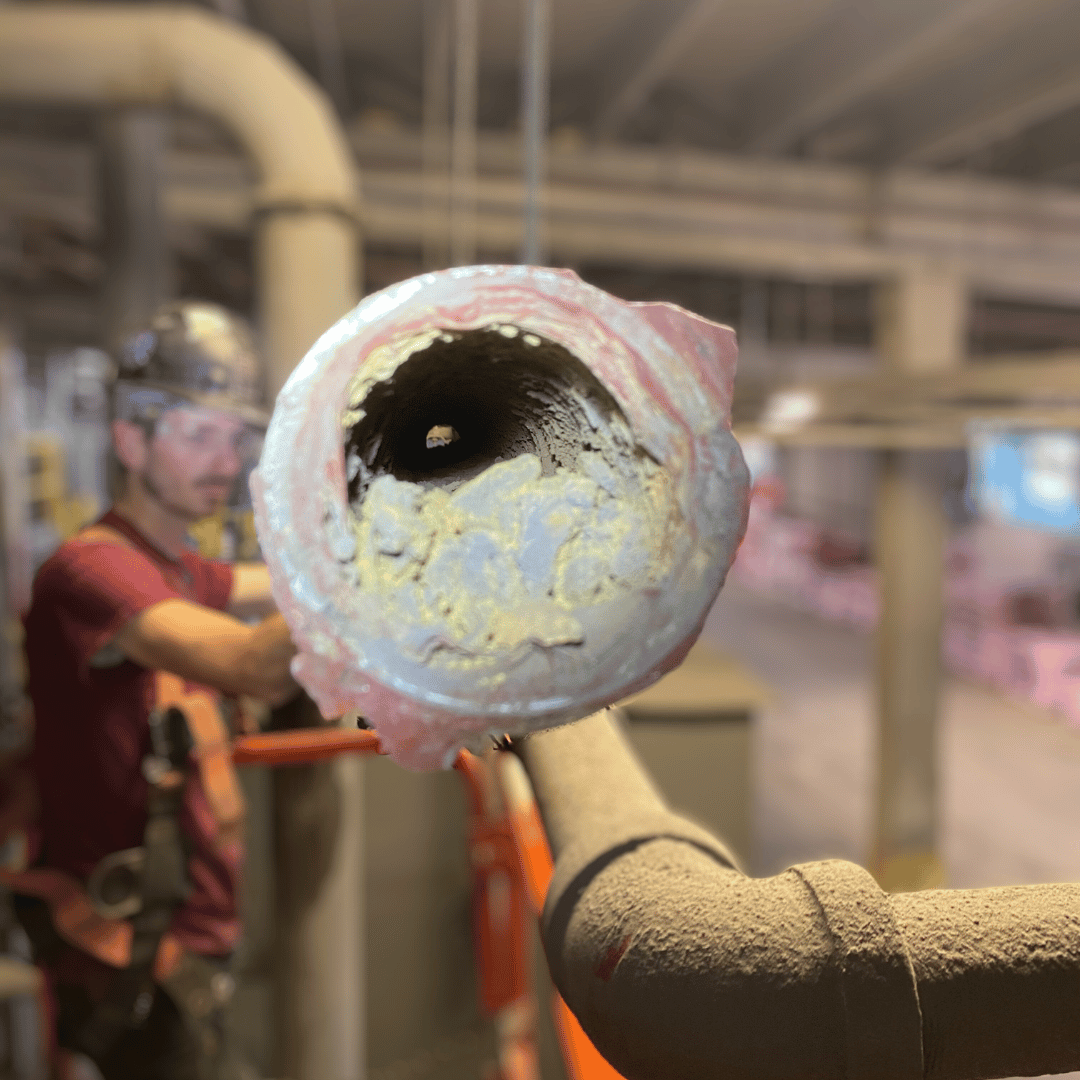

- ● Piping: Inspectors assess the condition of pipes for signs of corrosion, leaks, or damage. This includes both visible pipes and those hidden within walls or underground.

-

- ● Fixtures and Appliances: Faucets, toilets, sinks, water heaters, and other fixtures are checked for proper functioning, leaks, or inefficiencies. Any worn-out or malfunctioning components may need repair or replacement.

-

- ● Drainage Systems: Drainage systems are inspected to ensure proper flow and prevent clogs or backups. This includes checking drainpipes, traps, and vents for obstructions or damage.

-

- ● Backflow Prevention: Facilities with backflow prevention devices must ensure these devices are functioning correctly to prevent contamination of the potable water supply. Inspections verify the integrity and effectiveness of backflow prevention measures.

-

- ● Water Quality: In some cases, water quality testing may be part of the inspection process to ensure compliance with health and safety standards. This includes testing for contaminants such as lead or bacteria.

-

- ● Emergency Preparedness: Inspections may also include evaluating emergency shut-off valves, fire suppression systems, and other safety measures to ensure they are operational in case of emergencies.

Benefits of Regular Plumbing Infrastructure Inspection

- ● Cost Savings: Early detection of plumbing issues allows for timely repairs, preventing more extensive damage and costly repairs down the line.

-

- ● Extended Equipment Lifespan: Proper maintenance and timely repairs help prolong the lifespan of plumbing equipment and fixtures, reducing the need for premature replacements.

-

- ● Improved Reliability: A well-maintained plumbing system is less likely to experience unexpected breakdowns or disruptions, ensuring continuous operations.

-

- ● Enhanced Reputation: Maintaining a safe and functional plumbing system reflects positively on the reputation of the facility, instilling confidence in employees, customers, and stakeholders.

-

- ● Regulatory Compliance: Regular inspections help ensure compliance with local building codes, health regulations, and environmental standards, avoiding potential fines or legal consequences.

Conclusion

Plumbing infrastructure inspection is a crucial aspect of maintaining the functionality, safety, and compliance of industrial and commercial facilities. By conducting regular inspections and addressing any issues promptly, facility managers can prevent costly repairs, ensure a safe working environment, and optimize the efficiency of plumbing systems. Investing in proactive maintenance today can lead to significant cost savings and operational benefits in the long run.