The Importance of Pressure Testing

Fire extinguishers are subjected to high pressure over time, and even small leaks or pressure drops can compromise their effectiveness in an emergency. Regular pressure testing ensures that extinguishers are fully charged and ready to use.

Benefits of Fire Extinguisher Pressure Testing

- ● Ensure Equipment Reliability: Proper pressure testing guarantees that your fire extinguishers will work as intended when needed.

- ● Stay Compliant: NFPA 10 and OSHA regulations require regular pressure testing to ensure safety compliance.

- ● Prevent Costly Replacements: Identifying pressure issues early can extend the life of your fire extinguishers, saving on replacement costs.

Our Fire Extinguisher Pressure Testing Process

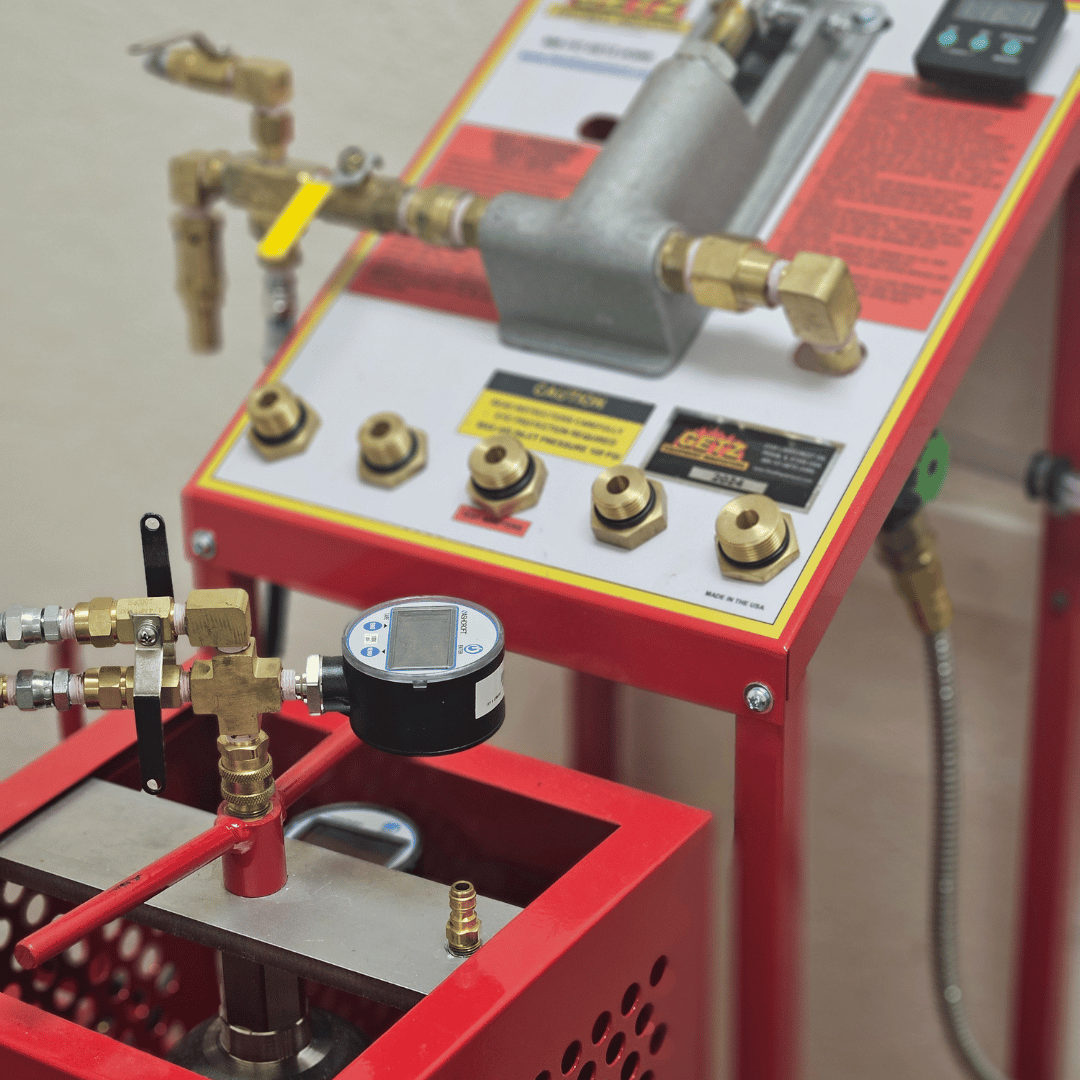

Our certified technicians use specialized equipment to test the pressure of your fire extinguishers, ensuring they meet the required safety standards. If issues are found, we provide recommendations for repair or replacement.

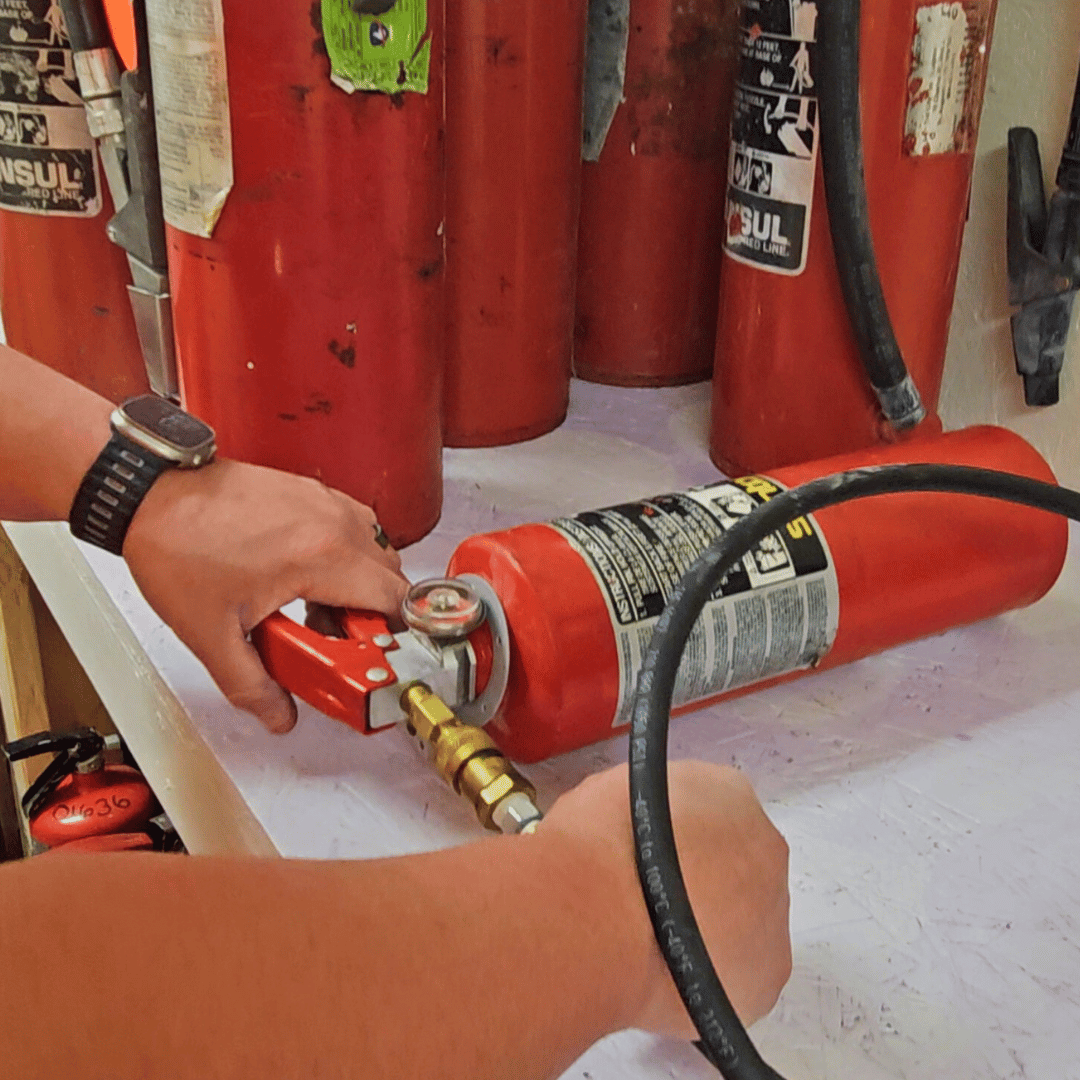

- Pressure Gauge Reading: We begin by checking the pressure gauge to ensure it falls within the optimal range for the type of fire extinguisher.

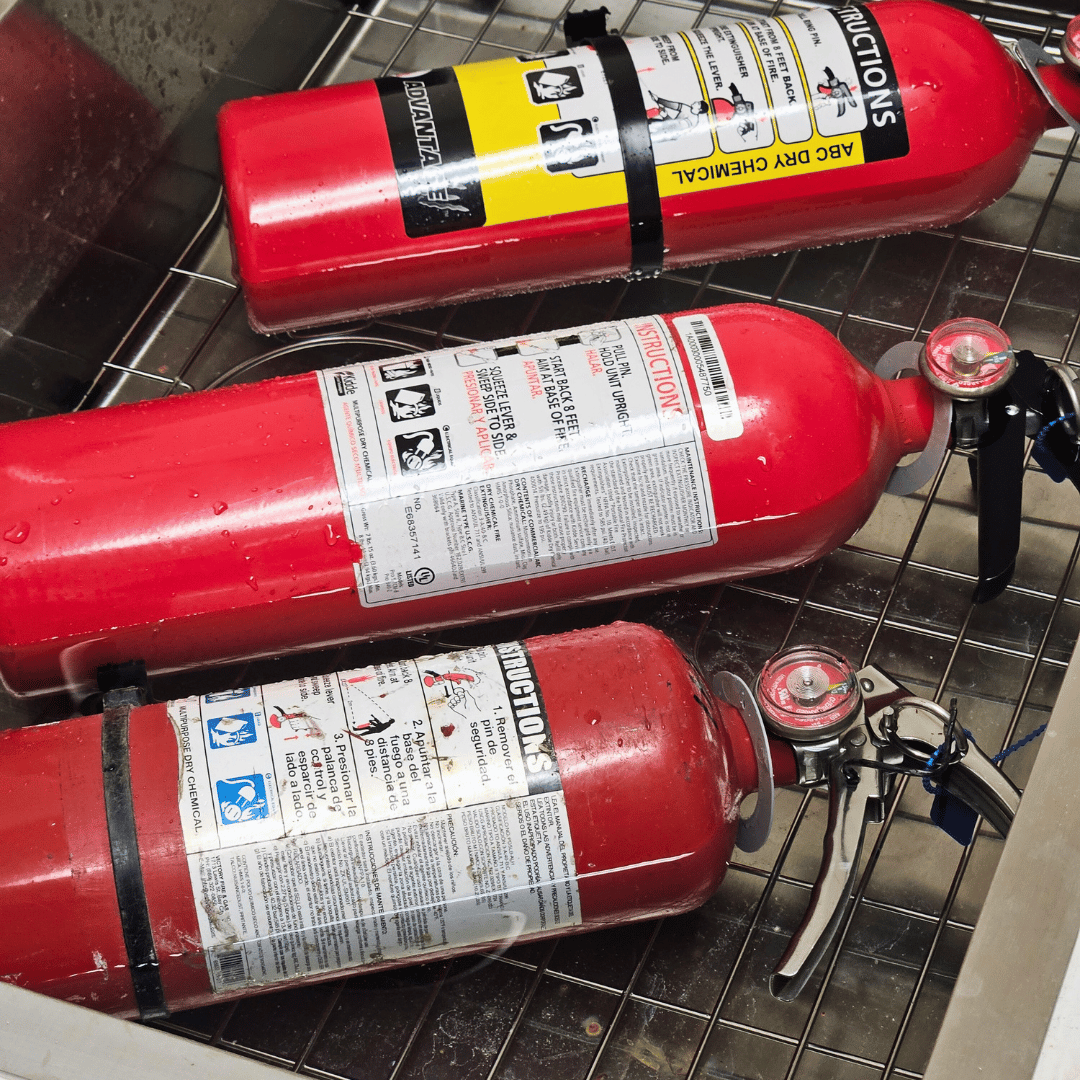

- Hydrostatic Testing: If the extinguisher is due for its required hydrostatic test (every 12 years for most types), we perform a detailed internal inspection and pressure test to confirm the integrity of the cylinder.

- Leak Detection: We inspect for any leaks or signs of pressure loss that may indicate a faulty cylinder.

- Testing Results & Documentation: Once testing is complete, we provide detailed documentation of the test results and update the service tags to reflect compliance with NFPA 10 standards.

Compliance & Safety

Regular pressure testing is required by NFPA 10 and OSHA to verify that fire extinguishers are properly pressurized and will function in the event of an emergency. Neglecting pressure testing can lead to non-compliance, fines, or, worse, equipment failure during a fire.

Key Benefits

- ● Maintain compliance: Meet NFPA 10 and OSHA regulations.

- ● Ensure readiness: Fire extinguishers are fully pressurized and ready for use.

- ● Prevent malfunction: Avoid equipment failure in emergencies caused by under-pressurization or leakage.

Why Choose Us for Pressure Testing?

With years of experience in fire protection services, we specialize in providing pressure testing that meets the needs of industrial and commercial facilities. Our team is certified and experienced in performing all types of pressure tests, ensuring your fire extinguishers are safe and compliant.

What Sets Us Apart

- ● Certified Technicians: Our team is fully trained and certified to carry out hydrostatic testing and pressure checks for all types of fire extinguishers.

- ● State-of-the-Art Equipment: We use the latest technology to perform precise and reliable pressure testing.

- ● Comprehensive Service: From testing to recharging and repair, we offer a full range of services to keep your fire extinguishers in top condition.

FAQ Section

Q: How often do fire extinguishers need to be pressure tested?

A: Fire extinguishers typically require a hydrostatic test every 12 years, but some types may need testing more frequently. Our team can assess your equipment and ensure all testing schedules are met.

Q: What is hydrostatic testing?

A: Hydrostatic testing is a procedure where a fire extinguisher cylinder is filled with water and pressurized to test its integrity. It ensures that the cylinder can safely hold pressure without leaking or failing.

Q: What happens if my extinguisher fails the pressure test?

A: If a fire extinguisher fails the pressure test, it must be replaced or repaired to ensure it meets safety standards. We provide recommendations based on the condition of your equipment.