Understanding Electrical Safety Inspections

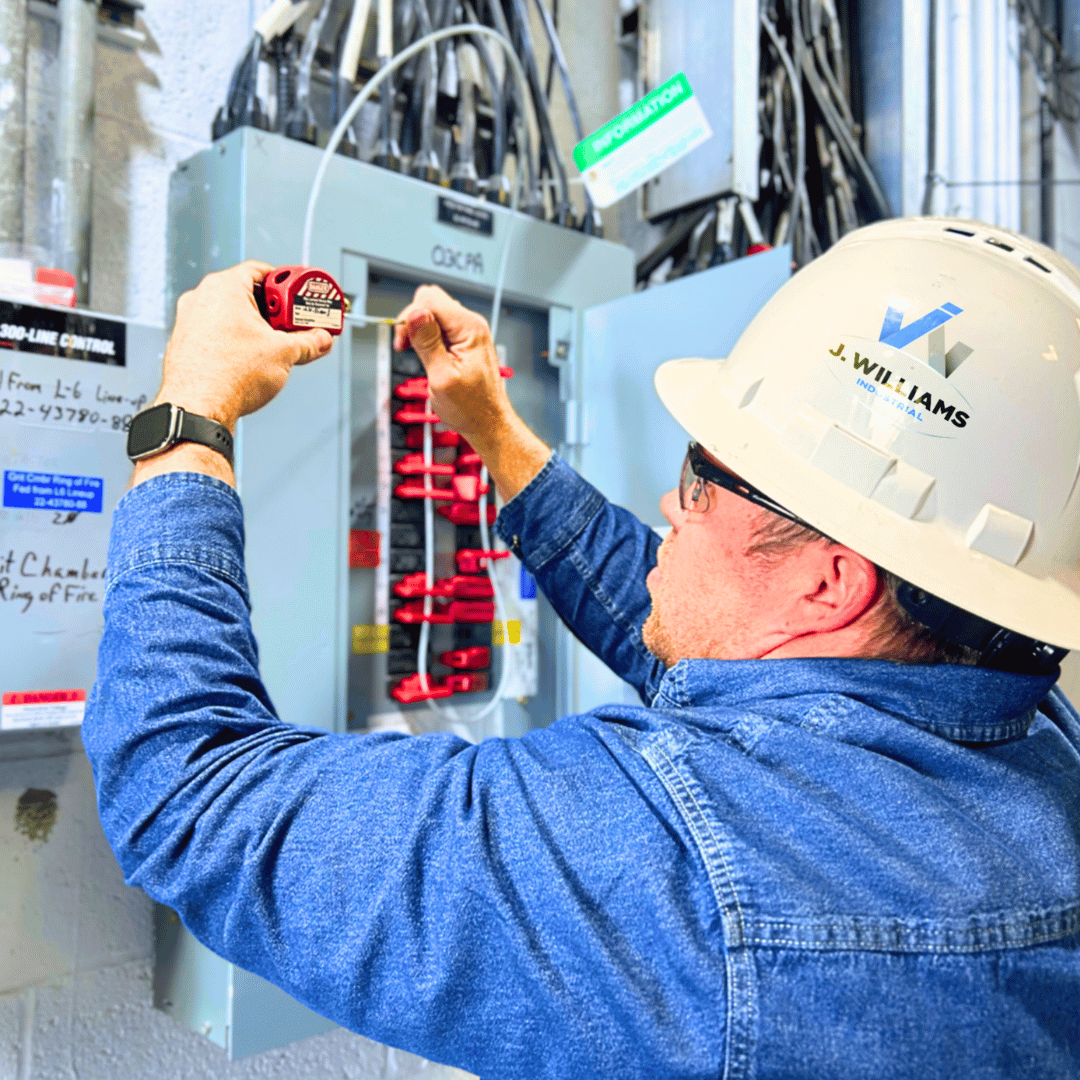

Electrical safety inspections are comprehensive assessments of electrical systems and equipment to ensure compliance with regulatory standards and best practices. These inspections are conducted by qualified professionals and aim to identify potential hazards, prevent accidents, and promote a safe working environment.

Components of Electrical Safety Inspections

- ● Visual Inspection: A visual examination of electrical components, including wiring, connections, switches, and outlets, to detect signs of damage, wear, or improper installation.

-

- ● Testing and Measurements: Use of specialized equipment to measure voltage, current, resistance, and insulation resistance to assess the performance and integrity of electrical systems.

-

- ● Code Compliance Review: Evaluation of electrical installations and equipment to ensure compliance with national and local electrical codes, standards, and regulations.

-

- ● Documentation and Reporting: Documentation of inspection findings, including observations, recommendations, and corrective actions, in comprehensive inspection reports.

Importance of Regular Compliance Checks

Regular safety compliance checks are crucial for several reasons:

Preventive Maintenance: Identifying and addressing potential safety hazards before they escalate into serious issues, minimizing the risk of electrical fires, shocks, and accidents.

Legal Compliance: Ensuring compliance with regulatory requirements and standards, reducing the risk of fines, penalties, and liability in the event of non-compliance.

Equipment Reliability: Maintaining the reliability and performance of electrical systems and equipment, reducing downtime, repair costs, and operational disruptions.

Occupational Safety: Protecting the health and safety of personnel, contractors, and occupants by mitigating electrical hazards and creating a safe working environment.

Benefits of Regular Compliance Checks

Regular safety compliance checks offer numerous benefits to businesses and property owners:

- ● Risk Mitigation: Identifying and addressing potential electrical hazards proactively, reducing the likelihood of accidents, injuries, and property damage.

-

- ● Cost Savings: Minimizing repair and replacement costs associated with electrical failures, downtime, and non-compliance penalties.

-

- ● Enhanced Reputation: Demonstrating a commitment to safety and compliance, enhancing the reputation and credibility of businesses and organizations.

-

- ● Peace of Mind: Providing peace of mind to stakeholders, employees, and occupants, knowing that electrical systems are safe, reliable, and compliant.

Conclusion

Regular safety compliance checks are essential for ensuring electrical safety in industrial and commercial environments. By conducting thorough electrical safety inspections, businesses can identify and address potential hazards, maintain compliance with regulatory standards, and create a safe working environment for employees and occupants.